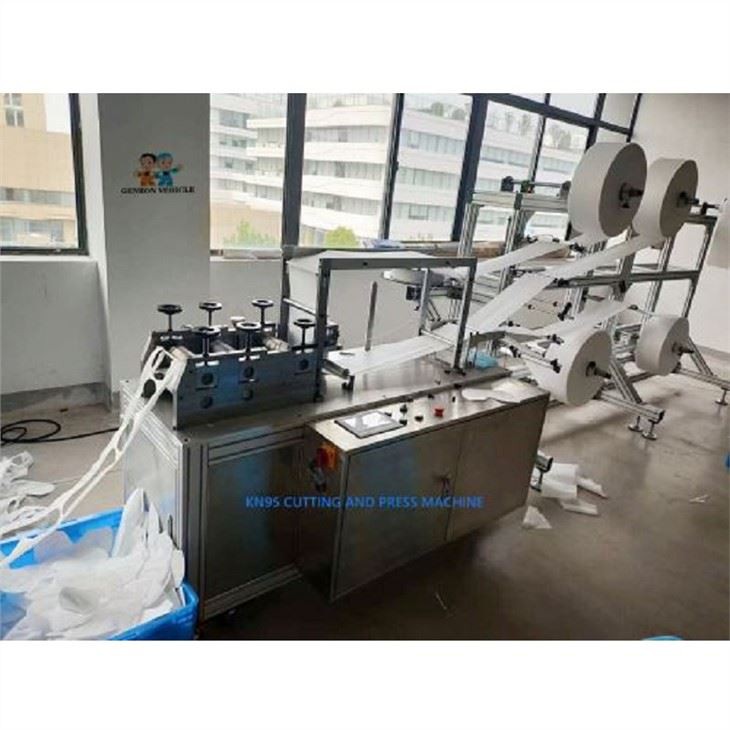

KN95 Semi-automatic Mask Making Machine

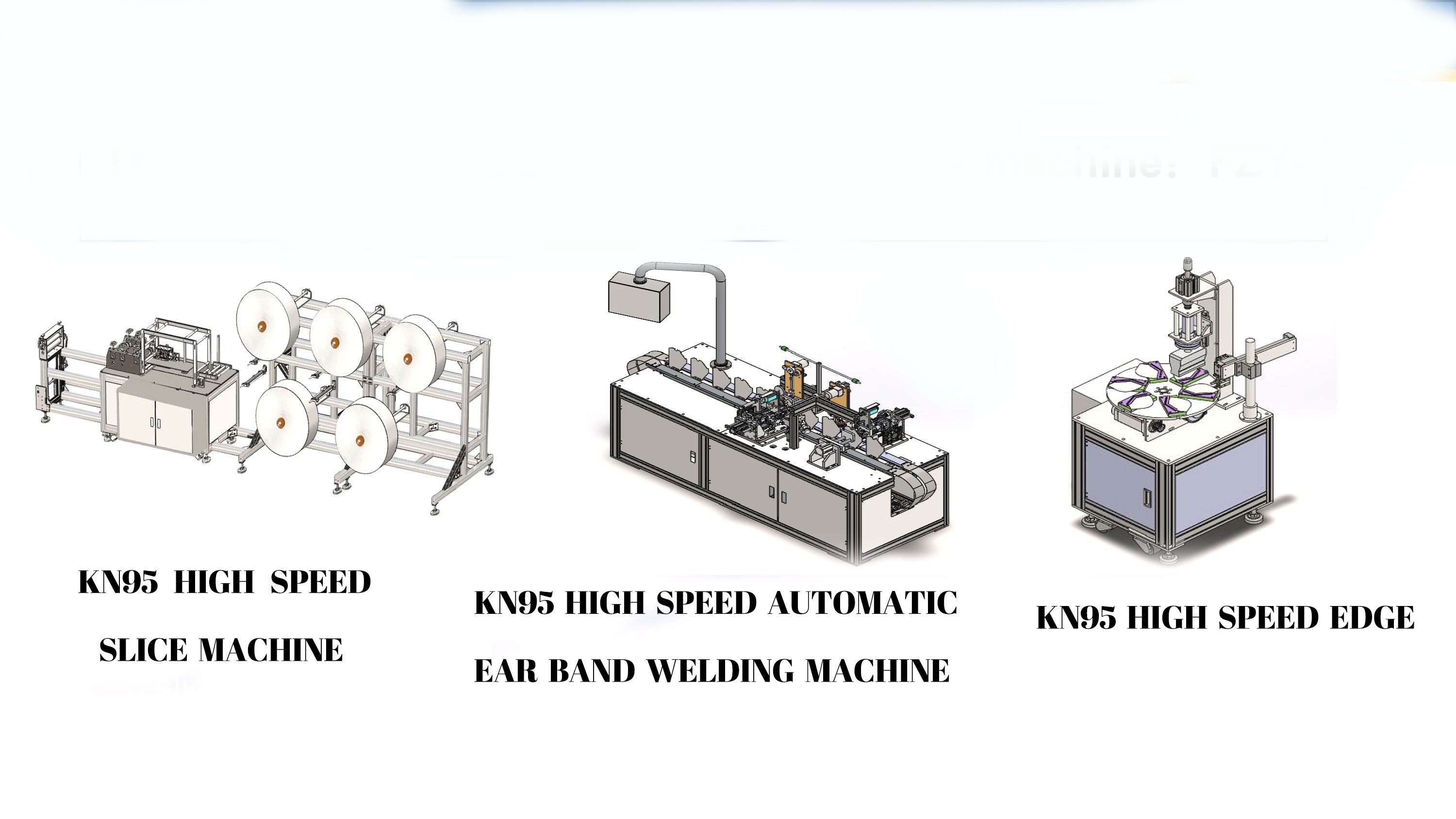

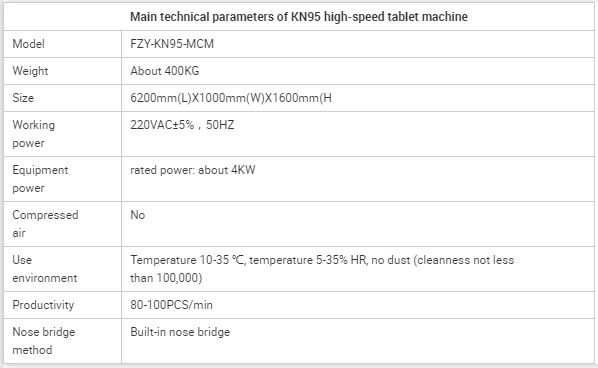

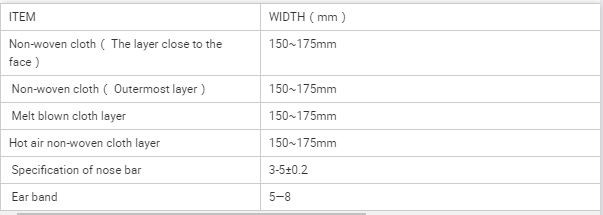

The KN95 Semi-automatic Mask Making Machine consist of three parts : 1.KN95 Mask Cutting&press Machine each minute produce 80 pieces masks 2.Mask Ear-Loop Machine 20 pcs mask each minute 3.Mask Sewing Machine/ Mask Edge Sealer : 22 pcs each minute If you want order one KN95 MASK machine ,should be order one Mask Cutting& Press machine two units Mask Ear-Loop Machine and two units Mask Edge Sealer

Send InquiryChat Now Hot Tags: kn95 semi-automatic mask making machine, China, suppliers, factory, wholesale, cheap, in stock, made in China, 3 Axles Skeleton Semi Trailer, Caterpillar Box Truck Trailer, 4 Axles Container Transport Semi Trailer, Fuel Delivery Truck Aluminum Oil Tank Truck, Stake Semi Trailer, End Dump Semi Trailer Capacity Sale In Australia

- Previous: Automatic Disposable Mask Making Machine

- Next: No Information

Related Products